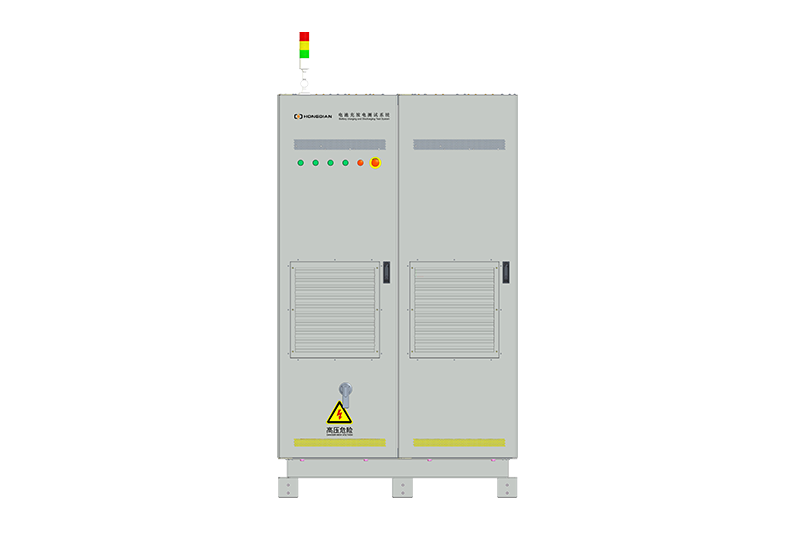

64 channel battery charging and discharging test integrated battery cabinet

product details

Mainly used for electrical performance testing of high power and high-energy secondary batteries (power batteries, energy storage batteries, etc.), such as battery cycle life testing, capacity testing, DC internal resistance testing, charge and discharge characteristic testing, deep discharge testing, battery consistency testing, rate charge and discharge testing, etc. It can achieve integrated monitoring of charge and discharge data.

Technical Parameter

AC input parameters | |||

Input power supply |

AC 380V±10% 50/60±5Hz |

Inputimpedance |

≥1MΩ |

Power factor |

≥99%(Full load) |

Feedback efficiency (MAX) |

≥90%(Full load) |

THDI |

≤5%(Full load) |

||

DC output parameters | |||

voltage precision |

±0.05%FS |

Electric current precision |

±0.05%FS |

voltage Resolution |

1mV |

Current Resolution |

1mA |

Current response time |

10ms(10%FS ~ 90%FS) |

Auxiliary channel type |

NTC |

Charge and discharge conversion time |

20ms(-90%FS ~ 90%FS) |

Channel control mode |

All channels can be controlled independently |

Step function characteristics | |||

Minimum data recording time |

10ms |

Cycle number |

65535 |

Number of work steps |

2000 |

Loop nesting |

5 |

Support experimental esting |

Battery cycle life test、Battery pack capacity test、Battery charge/discharge characteristic test、Charge retention test of battery pack、Charge and discharge efficiency test of battery pack、Charge and discharge efficiency test of battery pack |

||

Charge and discharge mode |

Static, pause, constant current charging CC, constant voltage charging CV, constant resistance charging CR, constant current and constant Voltage charging CCCV, constant power charging CP, constant current discharge DC, constant power discharge DP, constant resistance discharge DR, DC Internal Resistance Test (DCIR) |

||

Cut-off condition |

Voltage, current, capacity, energy, time, power, number of cycles, BMS parameters, custom advanced parameters (support one or more logic and or combination) |

||

Execution action type |

Jump, pause, protect, Next |

||

485/DBC File import |

Supports file editing, saving, and importing |

||

DcInternal Resistance Test (DCIR) |

SupportDCIRwork step,hardwarereal-imecalculation,supportgraphic twokindsoftesting |

||

Data export mode |

Export in Excel or CSV format |

||

Protection function | |||

AC side protection |

Powergridvoltage over/under、voltageprotection,surge、protection,anti-island protection, over and under frequencyprotection,hardware over temperature protection, self-detection protection, etc |

||

DC side protection |

under voltage protection, hardware over temperature protection, battery channel line reverse connection protection |

||

Battery side comprehensive |

Upper and lower limit protection of the total battery voltage, upper and lower limit protection of the battery voltage, upper and lower limit protection of the battery temperature, upper and lower limit protection of the battery charge and discharge current, upper and lower limit protection of the battery capacity, BMS communication outage protection, network outage protection, etc |

||

Power failure data protection |

With memory power off protection function, it can effectively avoid data loss caused by power off or can continue to run at the process break point without modifying the process after the call |

||

Class of protection |

IP20 |

Cooling mode |

Forced air cooling |

operating temperature range |

0℃-45℃ |

noise |

≤80dB |

Main Testing Functions

Cycle Life Test

Capacity Test

Charge discharge characteristic test

DC internal resistance test

Overcharge/Over discharge Test

Third party linkage testing

Temperature characteristic test

CAN/RS485 communication

Customer usage site

Product Features

Global protection ensures worry free operation

• Voltage/current/upper and lower limits/capacity upper and lower limit protection;

• Over/under voltage/over frequency/over power protection for the power grid;

• Battery reverse connection protection;

• Equipment power-off continuity protection;

• Self diagnostic protection;

• Channel anomaly capture protection;

• Overheat protection;

• Protecting logs for traceability.

Introduction to battery testing equipment

Our 15V multi-channel battery charge and discharge test integrated equipment is a state-of-the-art solution designed for comprehensive battery testing. It is equipped with multiple channels, allowing for simultaneous testing of several batteries, which significantly improves testing efficiency.

With a voltage range of up to 15V, this device can accommodate a wide variety of batteries, from small-sized ones for portable electronics to larger ones used in power tools and electric vehicles. It supports both charge and discharge functions, enabling accurate assessment of battery performance under different working conditions.

Each channel is independently controllable, providing users with the flexibility to set different test parameters for each battery. This includes setting specific charge and discharge currents, voltages, and time limits. The equipment also features high-precision measurement capabilities, ensuring accurate data collection for battery capacity, internal resistance, and other crucial parameters.

In terms of safety, the device is equipped with multiple protection mechanisms. These safeguard against overcharging, over-discharging, over-current, and over-voltage situations, protecting both the batteries being tested and the equipment itself.

This 15V multi-channel battery charge and discharge test integrated equipment is ideal for battery manufacturers, research institutions, and quality control departments. It can be used for battery development, quality inspection, and performance evaluation, helping to enhance battery quality and reliability.

Company Profile

Shenzhen Hongda New Energy Co., Ltd. was established in 2014. It is a high-tech enterprise specializing in the research and development, production, and sales of battery testing systems, providing intelligent testing solutions for batteries.

Hongda New Energy has been deeply involved in the field of new energy for more than ten years, focusing on battery safety testing and bidirectional energy conversion technology. The company has strong technical strength and leads the development of multiple battery testing technologies. The company has more than 20 technology patents and a professional R&D team of over 35%. We always take "making batteries safer and energy more efficient" as our mission, and are committed to solving the core pain points of the industry through technological innovation.

Since its establishment, Hongda New Energy has served thousands of customers and its sales business covers the world. The product has been widely used in battery production lines and laboratories of major battery factories, new energy vehicle factories, energy storage battery supporting enterprises, testing institutions, and research institutes. With its perfect product quality and service quality, Hongda New Energy has been highly praised by customers.

1000V-1500V High Voltage High Current Battery Testing System

1000V-1500V High Voltage High Current Battery Testing System

32/48 channel battery charging and discharging test integrated battery cabinet

32/48 channel battery charging and discharging test integrated battery cabinet

40 channel battery charging and discharging test integrated battery cabinet

40 channel battery charging and discharging test integrated battery cabinet

64 channel battery charging and discharging test integrated battery cabinet

64 channel battery charging and discharging test integrated battery cabinet

80 channel battery charging and discharging test integrated battery cabinet

80 channel battery charging and discharging test integrated battery cabinet

High-Precision Battery Testing System for Enhanced Performance Monitoring 30V/60V/100V/120V

High-Precision Battery Testing System for Enhanced Performance Monitoring 30V/60V/100V/120V

High-Precision Battery Charge Discharge Test Systems for EV Manufacturers

High-Precision Battery Charge Discharge Test Systems for EV Manufacturers

Precision Battery Test Racks for Cell Capacity & Internal Resistance Measurement

Precision Battery Test Racks for Cell Capacity & Internal Resistance Measurement

Multi-Channel Battery Testing Equipment for Parallel Performance Analysis

Multi-Channel Battery Testing Equipment for Parallel Performance Analysis