Trusted Wholesale Battery Safety Testing Quotes from Reliable Factories

Ensuring the safety of battery products is our top priority through comprehensive Battery Safety Testing. We offer extensive testing services for wholesalers, manufacturers, and factories, helping you meet the highest safety standards. With advanced technology and methodologies, we assess battery performance under various conditions. Our commitment to delivering accurate results quickly and efficiently has solidified our reputation in the industry. We provide tailored solutions to meet your specific requirements, enhancing compliance with safety regulations and bolstering your brand's credibility. By partnering with us, you gain access to expert insights and support throughout the testing process, all at competitive rates. Ensure your batteries are safe and ready to meet market demands—your peace of mind is only a test away!

10 Essential Tips For Battery Safety Testing Service Your End-to-End Solution

When it comes to battery safety testing services, ensuring a reliable end-to-end solution is paramount for manufacturers and suppliers around the globe. As the industry continues to grow, it is essential to adhere to the highest standards to maintain customer trust and compliance with regulations. Hongda New Energy, with its extensive experience serving over a thousand customers worldwide, understands the critical elements of effective battery safety testing. Here are ten essential tips that can guide procurement professionals in selecting the right testing partner. First and foremost, prioritize certification and accreditation when choosing a Battery Testing service. Look for laboratories that comply with international standards such as ISO 9001 and IEC 62133. Secondly, consider the range of testing services offered, including overcharge, thermal stability, and short circuit tests, to ensure comprehensive evaluation of battery safety. It’s also vital to examine the testing equipment and technologies utilized, as state-of-the-art tools lead to more accurate results. Additionally, assess the service provider's industry experience and track record to gauge their expertise in the field. Finally, maintaining open communication with your testing partner is crucial for addressing any concerns promptly and effectively. In an ever-evolving market, being able to adapt to new safety standards and technological advancements is key. By collaborating with a reputable partner like Hongda New Energy, you can enhance your battery safety protocols and secure your products’ reliability and performance on a global scale. With our commitment to excellence and a broad international network, we’re here to help you navigate the complexities of battery safety testing seamlessly.

10 Essential Tips For Battery Safety Testing Service Your End-to-End Solution

| Tip No. | Safety Tip | Description | Frequency |

|---|---|---|---|

| 1 | Visual Inspection | Check for physical damage, leaks, or corrosion. | Before each test |

| 2 | Temperature Monitoring | Ensure batteries are within safe operating temperature limits. | Continuous |

| 3 | Voltage Checking | Measure voltage levels and compare with nominal values. | Daily |

| 4 | Load Testing | Test under various load conditions to verify performance. | Monthly |

| 5 | Leakage Current Testing | Measure leakage current to ensure safety compliance. | Quarterly |

| 6 | Short-Circuit Testing | Simulate short circuits to assess protection features. | Annually |

| 7 | Cycle Life Testing | Assess battery durability over multiple charge/discharge cycles. | Biannually |

| 8 | Impact Testing | Test for physical impact resistance to prevent rupture. | As needed |

| 9 | Environmental Testing | Evaluate performance under extreme conditions (heat, cold, humidity). | Yearly |

| 10 | Documentation Review | Ensure all test results and procedures are thoroughly documented. | Ongoing |

Top 10 Battery Safety Testing Products Market Leader

M

Michael Anderson

The quality of the product exceeded my expectations! The support team was incredibly responsive and helpful.

04 July 2025

B

Barbara Miller

Wonderful product! The customer support team was incredibly helpful.

05 June 2025

J

Jenna Kim

Incredible item quality! The professionalism of the support team was equally impressive.

26 June 2025

A

Alice Williams

Very pleased with my purchase! The staff were incredibly helpful and professional.

12 June 2025

P

Patricia Bailey

I am thrilled with the purchase! The after-sales service was prompt and effective.

01 July 2025

S

Stephen Allen

I highly recommend this product! Their customer service was quickly responsive.

23 May 2025

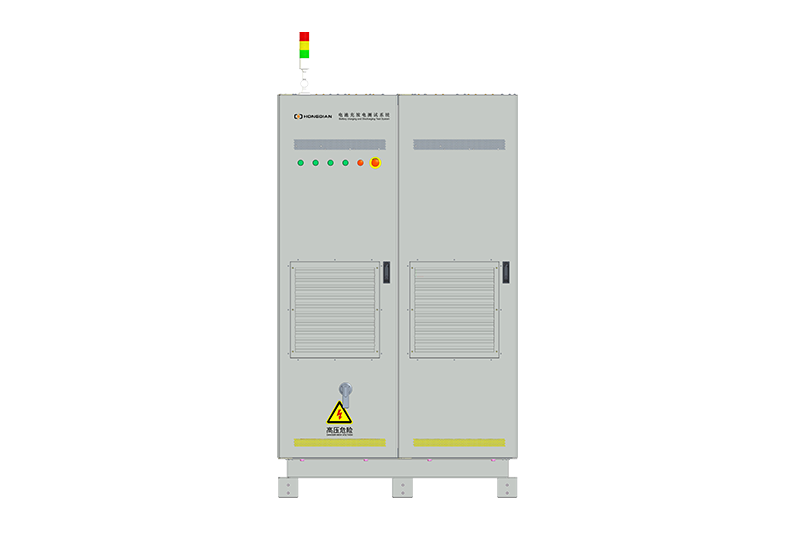

1000V-1500V High Voltage High Current Battery Testing System

1000V-1500V High Voltage High Current Battery Testing System  32/48 channel battery charging and discharging test integrated battery cabinet

32/48 channel battery charging and discharging test integrated battery cabinet  40 channel battery charging and discharging test integrated battery cabinet

40 channel battery charging and discharging test integrated battery cabinet  64 channel battery charging and discharging test integrated battery cabinet

64 channel battery charging and discharging test integrated battery cabinet  80 channel battery charging and discharging test integrated battery cabinet

80 channel battery charging and discharging test integrated battery cabinet  High-Precision Battery Testing System for Enhanced Performance Monitoring 30V/60V/100V/120V

High-Precision Battery Testing System for Enhanced Performance Monitoring 30V/60V/100V/120V  High-Precision Battery Charge Discharge Test Systems for EV Manufacturers

High-Precision Battery Charge Discharge Test Systems for EV Manufacturers  Precision Battery Test Racks for Cell Capacity & Internal Resistance Measurement

Precision Battery Test Racks for Cell Capacity & Internal Resistance Measurement  Multi-Channel Battery Testing Equipment for Parallel Performance Analysis

Multi-Channel Battery Testing Equipment for Parallel Performance Analysis