Redefining Energy Storage: How High-Precision Battery Testers are Driving the New Energy Revolution

The global shift toward new energy vehicles and large-scale energy storage systems marks a pivotal moment in technological history. At the core of this transition lies the battery—the indispensable powerhouse that determines the performance, safety, and longevity of everything from electric cars to grid-scale power banks. As battery technology accelerates, so too must the precision and sophistication of the equipment used to test them. This escalating demand for rigorous, high-accuracy validation has thrust advanced battery tester and Battery Health Checker systems into the spotlight, establishing them as critical infrastructure for the entire new energy ecosystem.

Pioneering this charge is Shenzhen Hongda New Energy Co., Ltd. , a leader in developing High-Precision Battery Charging and Discharging Test Systems. Their systems are not just incremental upgrades; they represent a fundamental leap forward, integrating cutting-edge digital control and energy-saving technologies to meet the stringent requirements of modern battery R&D, production, and quality control.

The New Gold Standard for Accuracy and Efficiency

In the world of Battery Testing, minor deviations in measurement can lead to catastrophic errors in product lifetime prediction and safety assessment.Shenzhen Hongda New Energy Co., Ltd. has directly addressed this challenge, setting a formidable new industry benchmark with a declared Voltage/current accuracy of $0.05\% \text{ FS}$. This level of precision is paramount for characterising next-generation battery chemistries—especially those that rely on extremely tight voltage windows for optimal performance and safety. For manufacturers of premium electric vehicles and high-density energy storage, this ensures that the data used to validate battery pack performance is unimpeachably accurate. Such high-fidelity measurements are essential for any credible Automotive battery tester system aiming for global regulatory compliance and consumer trust.

Furthermore, the conversation around new energy is intrinsically linked to sustainability. A core feature of the company’s advanced systems is their commitment to efficiency through Energy saving feedback. In traditional battery cycling, the energy discharged from the battery is simply wasted as heat. In contrast, Shenzhen Hongda New Energy Co., Ltd.’s technology incorporates regenerative principles, feeding the discharged energy back into the grid or a local power bus. This not only dramatically reduces the operational cost of running extensive, long-duration battery cycle tests—which can span thousands of hours—but also aligns perfectly with the overarching environmental goals of the new energy sector. This move from power consumption to power regeneration is a major step toward making battery testing itself a more sustainable practice.

Dual Digital Control: The Engine of Reliability

The architecture of these advanced battery testers is a testament to modern power electronics and digital signal processing. The systems feature TI 28377 Dual Core DSP + IGBT/SIC Full Digital Circuit Design. This combination is far from accidental.

TI 28377 Dual Core DSP (Digital Signal Processor): The DSP provides the computational horsepower needed for high-speed, real-time control and data acquisition. Its dual-core architecture allows for parallel processing, meaning one core can manage the complex control algorithms while the other handles high-speed data logging and communication. This ensures exceptional responsiveness and stability, even during rapid charge/discharge transitions.

IGBT/SiC Power Modules: The use of Insulated Gate Bipolar Transistors (IGBTs) and, critically, Silicon Carbide (SiC) MOSFETs in the power stage signifies a move towards extremely high efficiency and faster switching speeds. SiC is a wide-bandgap semiconductor that allows the power stage to operate at higher temperatures and higher frequencies with minimal energy loss. This translates directly into a more compact, more efficient, and more responsive battery tester unit. The "Full Digital Circuit Design" ensures that every component is precisely managed, delivering the superior accuracy and reliability required for a world-class battery health tester.

This robust foundation supports a key operational feature: Constant current/constant voltage dual hardware loop control, low clamp voltage. Battery charging and discharging inherently involve switching between Constant Current (CC) and Constant Voltage (CV) modes. Implementing this dual hardware loop control ensures a seamless, instantaneous, and highly stable transition between these modes. Unlike software-based control that can introduce lag, the hardware-level control guarantees that the system reacts immediately to changes in the battery’s state, protecting the cell from overshooting or undershooting the target parameters. The benefit of a low clamp voltage further enhances the precision, particularly when testing cells at very low voltage points—a critical phase for safety and deep discharge characterization.

Intelligent Communication for the Connected Battery

The modern battery pack, especially for electric vehicles, is an intelligent system managed by a Battery Management System (BMS). Any effective Automotive battery tester must be able to communicate seamlessly with this BMS to monitor internal states, bypass safety circuits in controlled conditions, and accurately log diagnostic data.

Shenzhen Hongda New Energy Co., Ltd.’s systems are fully equipped to Support BMS 485/CAN communication and DBC import.

- CAN (Controller Area Network) and 485 (RS-485): These are the ubiquitous communication protocols in the automotive and industrial battery sectors, allowing the test system to read real-time data directly from the BMS—such as cell temperature, individual cell voltage, and State of Health (SoH).

- DBC Import: The Database CAN (DBC) file is the standard way to define and interpret CAN messages. The ability to import DBC files means that the test system can instantly understand the proprietary communication language of any given BMS, drastically simplifying setup and integration. This is a crucial feature for R&D labs and manufacturing lines that handle a variety of battery pack designs. This capability transforms the battery tester from a simple current source/sink into a powerful, intelligent diagnostic hub.

The Future of Battery Testing is Now

The exponential growth in electric mobility and renewable energy storage hinges entirely on the continuous improvement of battery technology. This necessitates an equally transformative evolution in testing equipment. The demanding needs of this industry—extreme accuracy, measurable efficiency, and intelligent integration—cannot be met by legacy equipment.

Shenzhen Hongda New Energy Co., Ltd.’s High-Precision Battery Charging and Discharging Test Systems provide the market with a sophisticated solution that addresses all these critical factors. From the high-efficiency Energy saving feedback and the industry-leading $0.05\% \text{ FS}$ accuracy, to the sheer power and stability offered by the Dual Core DSP and SiC Full Digital Circuit Design, these systems are engineered for the future. They are the essential tools that will help global manufacturers and R&D facilities accelerate the development of safer, longer-lasting, and more efficient batteries. By leveraging these advanced battery testers and integrated communication capabilities, companies worldwide can ensure the highest standard of battery health checker validation, securing their place in the burgeoning new energy economy.

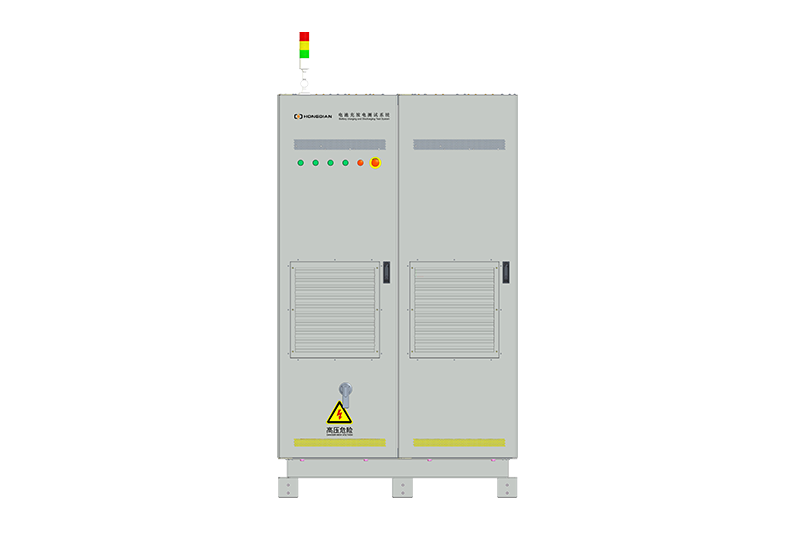

1000V-1500V High Voltage High Current Battery Testing System

1000V-1500V High Voltage High Current Battery Testing System  32/48 channel battery charging and discharging test integrated battery cabinet

32/48 channel battery charging and discharging test integrated battery cabinet  40 channel battery charging and discharging test integrated battery cabinet

40 channel battery charging and discharging test integrated battery cabinet  64 channel battery charging and discharging test integrated battery cabinet

64 channel battery charging and discharging test integrated battery cabinet  80 channel battery charging and discharging test integrated battery cabinet

80 channel battery charging and discharging test integrated battery cabinet  High-Precision Battery Testing System for Enhanced Performance Monitoring 30V/60V/100V/120V

High-Precision Battery Testing System for Enhanced Performance Monitoring 30V/60V/100V/120V  High-Precision Battery Charge Discharge Test Systems for EV Manufacturers

High-Precision Battery Charge Discharge Test Systems for EV Manufacturers  Precision Battery Test Racks for Cell Capacity & Internal Resistance Measurement

Precision Battery Test Racks for Cell Capacity & Internal Resistance Measurement  Multi-Channel Battery Testing Equipment for Parallel Performance Analysis

Multi-Channel Battery Testing Equipment for Parallel Performance Analysis