Shenzhen Hongda New Energy Successfully Supplies 36 High-Precision Battery Test Systems, Reinforcing Its Industry Leadership

Shenzhen Hongda New Energy Technology Co., Ltd. has recently completed the delivery and installation of 36 high-precision battery test systems for a major client, further solidifying its reputation as a trusted provider of advanced Battery Test Equipment. This large-scale project highlights the company’s capabilities in manufacturing, logistics, and technical support, making it a go-to partner for global energy industry players.

The Importance of Precision in Battery Testing

As the demand for efficient and reliable energy storage grows, accurate battery discharge and charge testing has become indispensable. Whether for electric vehicles (EVs), renewable energy storage, or consumer electronics, evaluating performance, safety, and longevity requires highly precise testing systems. Battery aging tests, in particular, help manufacturers predict lifecycle performance and ensure product durability. Hongda’s systems are designed to meet these critical needs, providing reliable data for R&D and quality control.

Advanced Technical Specifications

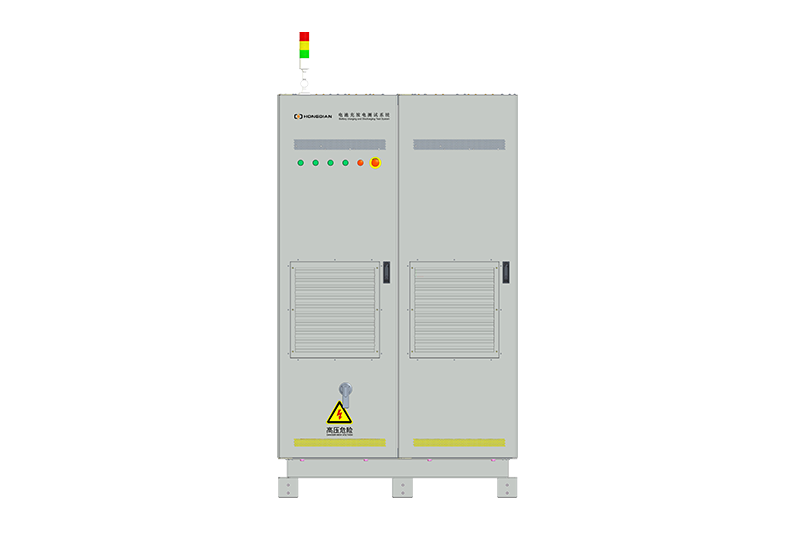

The deployed battery test systems feature cutting-edge technology, including:

- High-Precision Measurement: Accurate voltage, current, and capacity monitoring for dependable results.

- Multi-Channel Testing: Support for simultaneous testing of multiple battery cells, modules, or packs, improving efficiency.

- Flexible Configurations: Adaptable setups for various battery types and sizes, from small consumer batteries to large industrial energy storage systems.

- Robust Software: Intuitive interface for designing custom tests, real-time monitoring, and detailed data analysis.

- Enhanced Safety Protections: Built-in mechanisms to prevent overcharging, overheating, and short circuits during extended battery aging tests.

These features make Hongda’s systems ideal for applications in EV manufacturing, energy storage projects, and research laboratories.

End-to-End Service and Support

A project of this scale requires meticulous planning and execution. Hongda’s team managed everything from initial system configuration and production to logistics, on-site installation, and personnel training. Each system was calibrated and tested before delivery, ensuring seamless integration into the client’s existing operations. This comprehensive approach minimizes downtime and maximizes productivity for customers.

Proven Industry Expertise

With a growing client base of over 10000+ companies worldwide, including battery manufacturers, automotive OEMs, and research institutions, Hongda has established itself as a leader in the battery test system industry. Its ability to deliver large orders on time and provide ongoing technical support has made it a preferred partner for organizations seeking reliable and scalable testing solutions.

Future-Ready Testing Solutions

As battery technology continues to evolve, Hongda remains committed to innovating and expanding its product offerings. The company’s focus on developing more advanced, efficient, and user-friendly battery test equipment ensures that it will continue to play a key role in supporting the global transition to clean energy.

Keywords:

Battery test system, battery tester, battery discharge and charge testing, battery aging, battery test equipment, battery cycler, energy storage test, EV battery testing, high-precision battery analysis, cycle life testing.

1000V-1500V High Voltage High Current Battery Testing System

1000V-1500V High Voltage High Current Battery Testing System  32/48 channel battery charging and discharging test integrated battery cabinet

32/48 channel battery charging and discharging test integrated battery cabinet  40 channel battery charging and discharging test integrated battery cabinet

40 channel battery charging and discharging test integrated battery cabinet  64 channel battery charging and discharging test integrated battery cabinet

64 channel battery charging and discharging test integrated battery cabinet  80 channel battery charging and discharging test integrated battery cabinet

80 channel battery charging and discharging test integrated battery cabinet  High-Precision Battery Testing System for Enhanced Performance Monitoring 30V/60V/100V/120V

High-Precision Battery Testing System for Enhanced Performance Monitoring 30V/60V/100V/120V  High-Precision Battery Charge Discharge Test Systems for EV Manufacturers

High-Precision Battery Charge Discharge Test Systems for EV Manufacturers  Precision Battery Test Racks for Cell Capacity & Internal Resistance Measurement

Precision Battery Test Racks for Cell Capacity & Internal Resistance Measurement  Multi-Channel Battery Testing Equipment for Parallel Performance Analysis

Multi-Channel Battery Testing Equipment for Parallel Performance Analysis