Why do batteries need to undergo aging testing?

introduction

In today's era of rapid technological development, batteries are an important source of energy for various electronic devices, transportation vehicles, etc. Their performance and quality directly affect the user experience, safety, and lifespan of the equipment. Whether it's mobile phones, new energy vehicles, or energy storage systems, batteries play a crucial role. However, batteries are gradually aging due to various factors during actual use, which makes Battery Aging Testing particularly important. So, why do batteries need to undergo aging testing? Next, we will discuss in detail from multiple aspects.

Evaluate battery performance stability

The performance of a battery includes multiple aspects such as capacity, internal resistance, and charge discharge performance, and the stability of these properties directly affects the actual performance of the battery. In the production process, even if the same production process and materials are used, there may be certain performance differences between different batches of batteries or different batteries within the same batch. Through aging testing, various working conditions of the battery in actual use can be simulated to comprehensively evaluate its performance. For example, in high-temperature aging testing, the battery is placed in an aging cabinet and an appropriate high-temperature environment is set up to simulate the high-temperature conditions that the battery may encounter in actual use. After a long period of high-temperature aging testing, observe and record the performance changes of the battery, such as capacity degradation, internal resistance increase, etc. If the battery experiences a significant decrease in capacity, a sharp increase in internal resistance, or unstable charging and discharging performance during the aging test, it indicates that the performance stability of the battery is poor and may not meet the requirements of actual use. Screening batteries with unstable performance through aging testing can ensure that the batteries entering the market have high quality and performance stability, thereby improving the overall quality and reliability of the product. Taking mobile phone batteries as an example, unstable battery performance may lead to short battery life, slow charging speed, and even sudden shutdown during use, seriously affecting the user's experience. By conducting aging tests and selecting batteries with stable performance, these problems can be effectively avoided and user satisfaction with the product can be improved.

Predicting battery lifespan

The service life of a battery is an indicator that users are very concerned about, as it directly affects the equipment's usage cost and replacement cycle. However, the lifespan of batteries is influenced by various factors such as usage environment, number of charge and discharge cycles, and charging and discharging methods, making it difficult to accurately predict through simple theoretical calculations. Aging testing can accelerate the aging process of batteries by simulating various conditions during actual use, thereby evaluating the service life of batteries in a shorter period of time. For example, by conducting multiple charge discharge cycle aging tests on the battery, simulating the charging and discharging process of the battery in actual use, and observing the decay of battery capacity. Based on the decay rate of battery capacity, the service life of the battery under normal usage conditions can be predicted. If the capacity of the battery decays too quickly in the aging test, it indicates that the battery's service life may be short, and it is necessary to consider replacing the battery more frequently or taking other measures to extend the battery's service life when designing the product. For new energy vehicles, the lifespan of the battery directly affects the vehicle's operating costs and market competitiveness. Accurately predicting the service life of batteries through aging testing can help car manufacturers design battery systems rationally, formulate reasonable quality assurance policies, and also provide consumers with a clearer understanding of the battery's service life when purchasing vehicles.

Discovering potential defects and safety hazards in batteries

During normal use, the battery may experience issues such as capacity degradation and increased internal resistance as time passes and the number of charge and discharge cycles increases. However, some potential defects and safety hazards may not manifest during the initial use of the battery, but as the battery ages, these issues may gradually become exposed, leading to serious safety accidents. For example, batteries may experience overheating, short circuits, and other hazards after long-term use, which can lead to fire, explosion, and other dangers. This not only threatens the user's life safety but also causes significant property damage. Previously, there were new energy vehicles that were not detected in a timely manner due to battery aging, and suddenly caught fire while driving, causing great panic among car owners and surrounding people. Aging testing can simulate various extreme environments that batteries may encounter in actual use, such as high temperature, low temperature, high humidity, as well as long-term, high-intensity charge and discharge cycle testing, comprehensively testing the performance and safety of batteries, and discovering potential defects and safety hazards in advance. For batteries with potential defects and safety hazards, timely improvement or elimination can be carried out to prevent them from entering the market, thereby ensuring the safety of consumers' lives and property. Aging testing is an important safety defense line in the research and production process of batteries, which can effectively reduce the probability of battery safety accidents.

Optimize battery design and production process

The results of aging testing can provide important reference for the design and production process of batteries. By analyzing aging test data, we can understand the performance changes of batteries under different conditions, identify key factors that affect battery performance and lifespan, and optimize battery design and production processes in a targeted manner. For example, if it is found during aging testing that the capacity of the battery decays rapidly in high temperature environments, it may be due to issues with the battery's heat dissipation design or poor stability of the materials used at high temperatures. To address these issues, the heat dissipation structure of the battery can be improved by selecting materials that are more resistant to high temperatures, thereby enhancing the performance and lifespan of the battery in high-temperature environments. For example, if it is found that the internal resistance of a battery increases too quickly after multiple charge and discharge cycles, it may be due to poor performance of the battery's electrode materials or electrolyte, and improvements need to be made to the electrode materials and electrolyte. By continuously optimizing the design and production process of batteries, the performance and quality of batteries can be improved, production costs can be reduced, and the market competitiveness of products can be enhanced. For battery manufacturers, aging testing is an important means to improve product quality and technological level.

Meet industry standards and regulatory requirements

With the widespread application of batteries in various fields, in order to protect the rights and safety of consumers, the industry has formulated a series of standards and regulations, which put forward strict requirements for the performance, safety and other aspects of batteries. Battery aging testing is one of the important means to verify whether the battery meets these standards and regulations. Only by conducting aging tests to prove that the performance and safety of the battery meet the requirements of relevant standards and regulations, can battery products enter the market for sale. For example, in the new energy vehicle industry, the country has clear regulations on the safety, energy density, cycle life, and other indicators of automotive batteries. Automobile manufacturers must conduct strict aging tests on batteries to ensure that they meet these standard requirements before putting vehicles into the market. Similarly, in the electronics industry, there are relevant standards and regulations both internationally and domestically that require aging testing of batteries to ensure the quality and safety of electronic products. Therefore, conducting battery aging testing is a necessary measure for enterprises to comply with industry standards and regulations, and it is also a necessary condition for products to enter the market.

Enhance market competitiveness

In fierce market competition, product quality and reliability are key factors for enterprises to win market share. By conducting aging tests on batteries, companies can select battery products with stable performance, long service life, and high safety, improve product quality and reliability, and thus enhance product market competitiveness. Consumers often pay attention to the performance and quality of batteries when purchasing electronic products, new energy vehicles, and other products. A battery product that has undergone rigorous aging testing can provide consumers with a higher sense of security and trust, thereby increasing their willingness to purchase the product. For example, a certain brand of mobile phone emphasizes in its promotion that its battery has undergone strict aging testing and has advantages such as long battery life and high safety, which will attract more consumers' attention and purchase. In addition, continuously optimizing the design and production process of batteries through aging testing can reduce production costs and give enterprises a certain price advantage, further enhancing market competitiveness. For battery manufacturers, aging testing is an important way to enhance their brand image and market competitiveness.

conclusion

In summary, battery aging testing is of great significance for evaluating battery performance stability, predicting battery service life, identifying potential defects and safety hazards, optimizing battery design and production processes, meeting industry standards and regulatory requirements, and enhancing market competitiveness. Whether for battery manufacturers, equipment manufacturers, or consumers, battery aging testing is a key link in ensuring product quality and safety, and improving user experience. In the future, with the continuous development of battery technology and the expansion of application fields, the importance of battery aging testing will become more prominent. Enterprises should attach great importance to battery aging testing, continuously improve testing methods and technologies, enhance the accuracy and reliability of testing, in order to produce battery products with better performance, higher quality, and better safety, and meet the needs of the market and consumers. At the same time, consumers should also pay attention to the relevant information of battery aging testing and choose products that have undergone strict aging testing to protect their rights and safety.

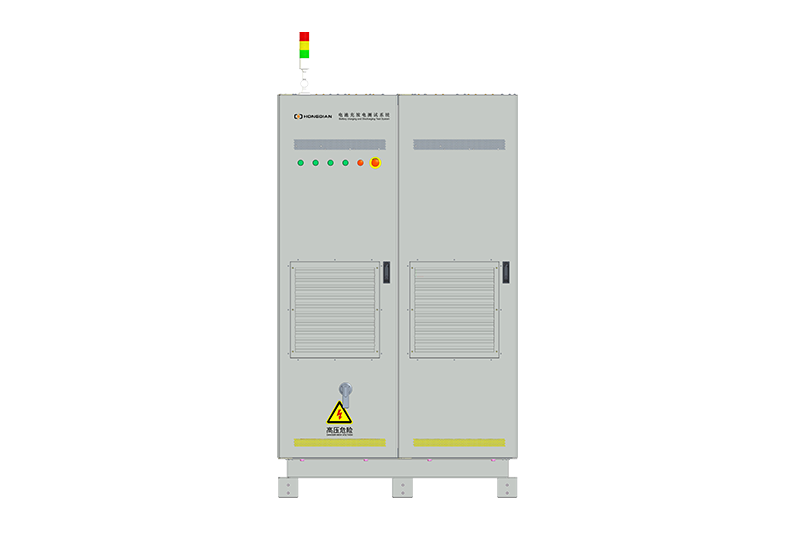

1000V-1500V High Voltage High Current Battery Testing System

1000V-1500V High Voltage High Current Battery Testing System  32/48 channel battery charging and discharging test integrated battery cabinet

32/48 channel battery charging and discharging test integrated battery cabinet  40 channel battery charging and discharging test integrated battery cabinet

40 channel battery charging and discharging test integrated battery cabinet  64 channel battery charging and discharging test integrated battery cabinet

64 channel battery charging and discharging test integrated battery cabinet  80 channel battery charging and discharging test integrated battery cabinet

80 channel battery charging and discharging test integrated battery cabinet  High-Precision Battery Testing System for Enhanced Performance Monitoring 30V/60V/100V/120V

High-Precision Battery Testing System for Enhanced Performance Monitoring 30V/60V/100V/120V  High-Precision Battery Charge Discharge Test Systems for EV Manufacturers

High-Precision Battery Charge Discharge Test Systems for EV Manufacturers  Precision Battery Test Racks for Cell Capacity & Internal Resistance Measurement

Precision Battery Test Racks for Cell Capacity & Internal Resistance Measurement  Multi-Channel Battery Testing Equipment for Parallel Performance Analysis

Multi-Channel Battery Testing Equipment for Parallel Performance Analysis